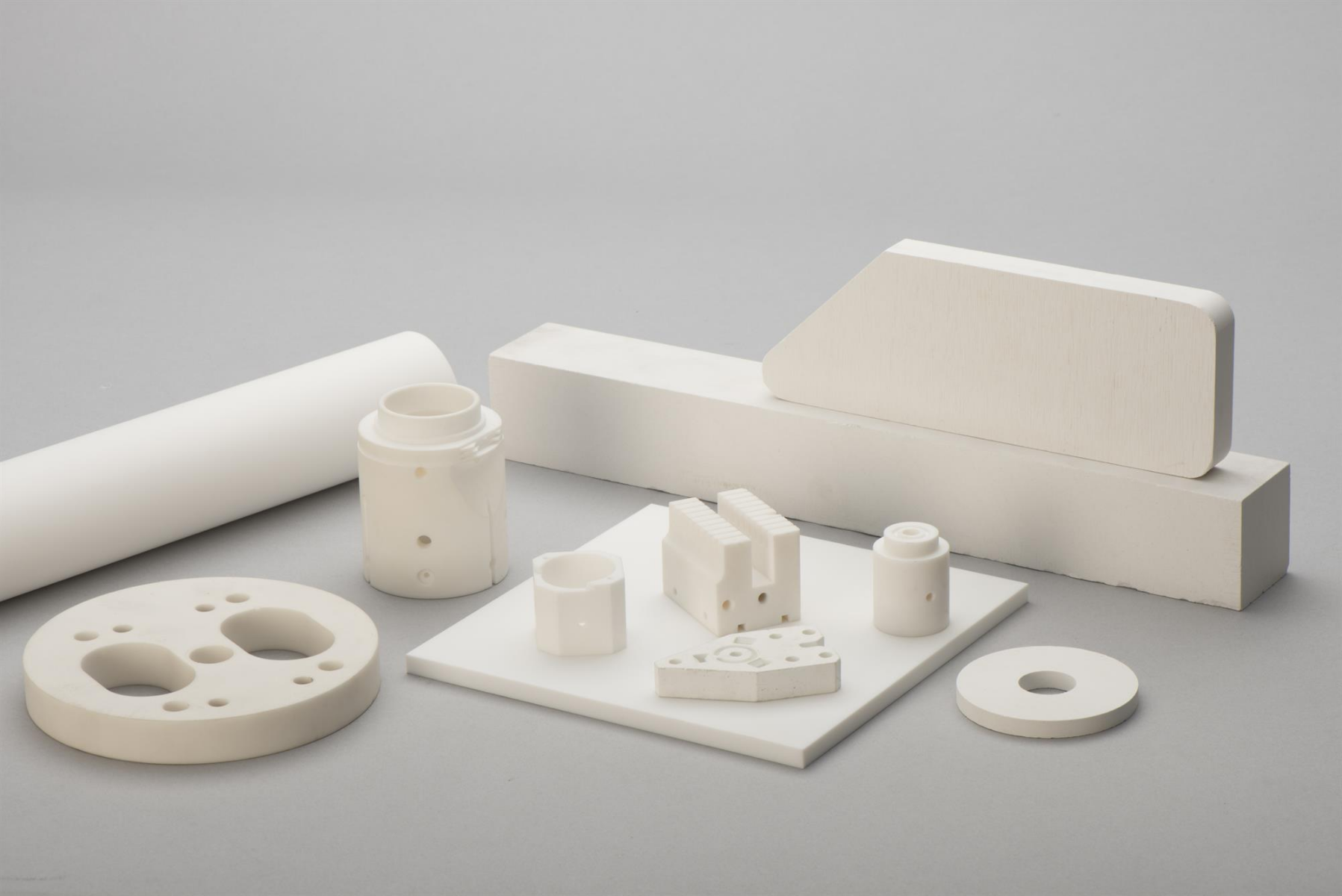

Sector Focus:All About Alumina

Otherwise known as Aluminium Oxide (Al2O3), Alumina is a white, nearly colourless crystalline substance. It’s produced by refining Bauxite, an ore mined from topsoil in certain tropical and subtropical regions. The Bayer process, discovered in 1887, is the primary method by which Alumina is extracted from Bauxite. Part of the oxide group of advanced ceramics, Alumina is a ceramic that is an extremely versatile material. It can be bonded and formed using a wide range of consolidation and sintering techniques.

Occurring naturally as the mineral Corundum, its gemstone forms are Sapphire and Ruby, which can both be produced synthetically from fine Alumina powder. Shaped by dual forces of application demands and technological advances, synthetic Sapphire in particular is a top choice for design engineers. Especially regarding extreme conditions of high temperature, high pressure and harsh chemical environments.

Alumina Properties

Alumina offers high performance whilst remaining cost effective. Its material properties include:

- Relatively high thermal conductivity

- High dielectric strength

- High heat resistance

- Very good chemical resistance

- High strength

- Extreme hardness and wear resistance

- Very good thermal shock resistance

Alumina Applications

Alumina is suitable for a wide range of applications within various areas and fields. Some examples include:

- Furnace tubes

- High-temperature vacuum furnaces

- Heat treating furnace rollers

- Radiant tubes

- Gas laser tubes

- Electrical insulator components

- Ceramic ballistic armour

- Crucibles and sample holders

- Electronic substrates

- Bone and dental implants

- Grinding media

For more information on Alumina, get in touch with a member of the Goodfellow team today. Alternatively, you can view our online catalogue here.